-

SA-12

SA-12

A staple add-on to all splitting and looper machines, the SA-12 uses heat to fuse sheets of converted material together, turning rectangular pieces into one long jointed roll. Easy and safe to use, add a Heat Sealing Machine to your long splitter for use in the garment and carpet industries.A staple add-on to all splitting and looper machines, the SA-12 uses heat to fuse sheets of converted material together, turning rectangular pieces into one long jointed roll. Easy and safe to use, add a Heat Sealing Machine to your long splitter for use in the garment and carpet industries.

-

SA-2AHLM

SA-2AHLM

The SA-2AHLS has a moveable cut head mounted on steel rails on either side of a slat conveyor. The cutting unit is also equipped with stands for operators to oversee the cutting process. Winding unit can be synchronized with cutting speed for optimized efficiency. A wide blade, a heavy duty and durable blade guide, and a grinding dust exhaust system ensures precise and consistent cutting.The SA-2AHLS has a moveable cut head mounted on steel rails on either side of a slat conveyor. The cutting unit is also equipped with stands for operators to oversee the cutting process. Winding unit can be synchronized with cutting speed for optimized efficiency. A wide blade, a heavy duty and durable blade guide, and a grinding dust exhaust system ensures precise and consistent cutting.

-

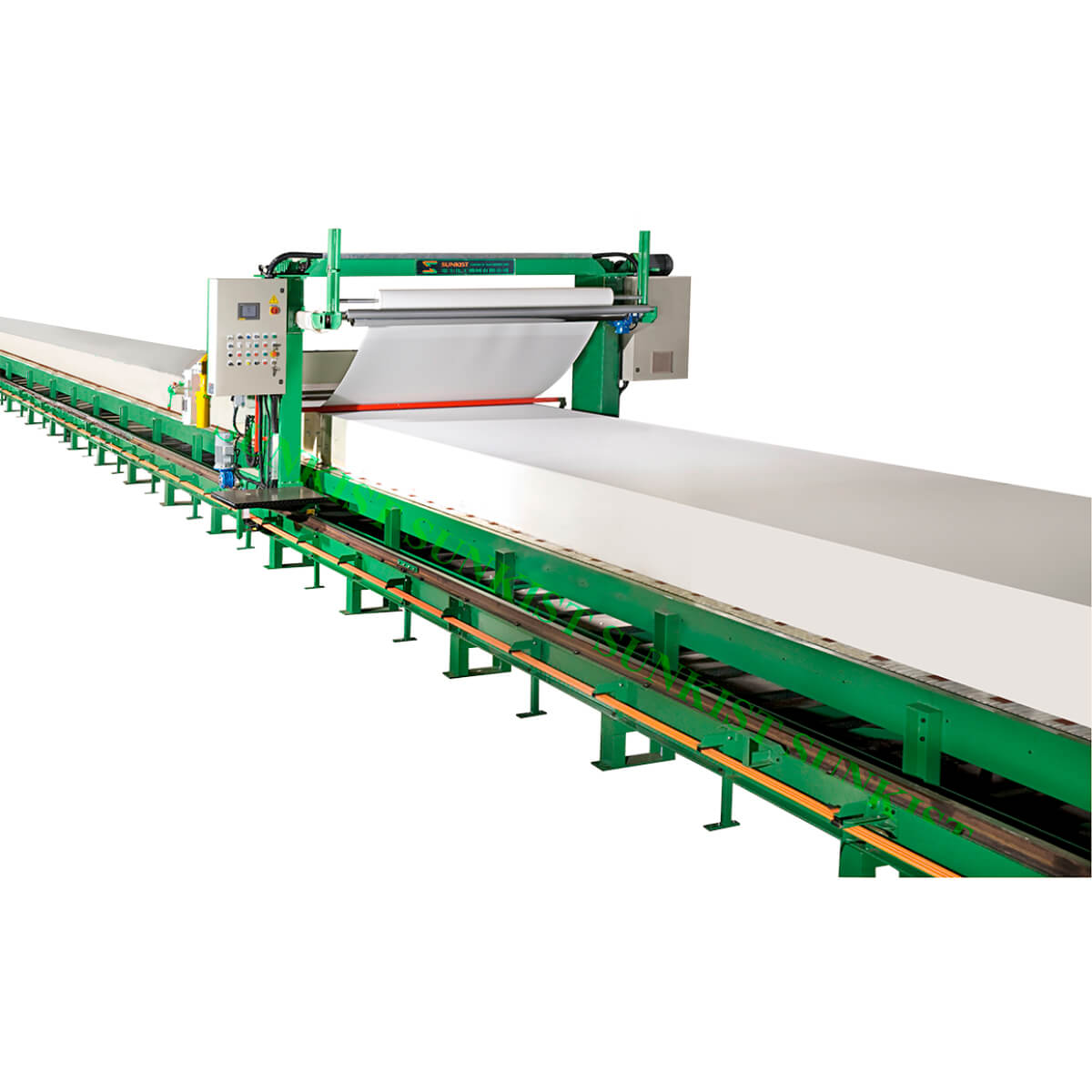

SA-2AHPL

SA-2AHPL

Sunkist’s best-selling long sheet cutter, the SA-2AHPL transforms polyurethane slabstock into rolled foam sheets. The cast-steel cut head is robust and designed to descend with the height of the foam to ensure even cuts of low tolerance every time. The vacuum system under the work surface further secures foam from misalignment. Side trimming blades and heat jointing are optional add-ons for efficient large-scale production.Sunkist’s best-selling long sheet cutter, the SA-2AHPL transforms polyurethane slabstock into rolled foam sheets. The cast-steel cut head is robust and designed to descend with the height of the foam to ensure even cuts of low tolerance every time. The vacuum system under the work surface further secures foam from misalignment. Side trimming blades and heat jointing are optional add-ons for efficient large-scale production.

-

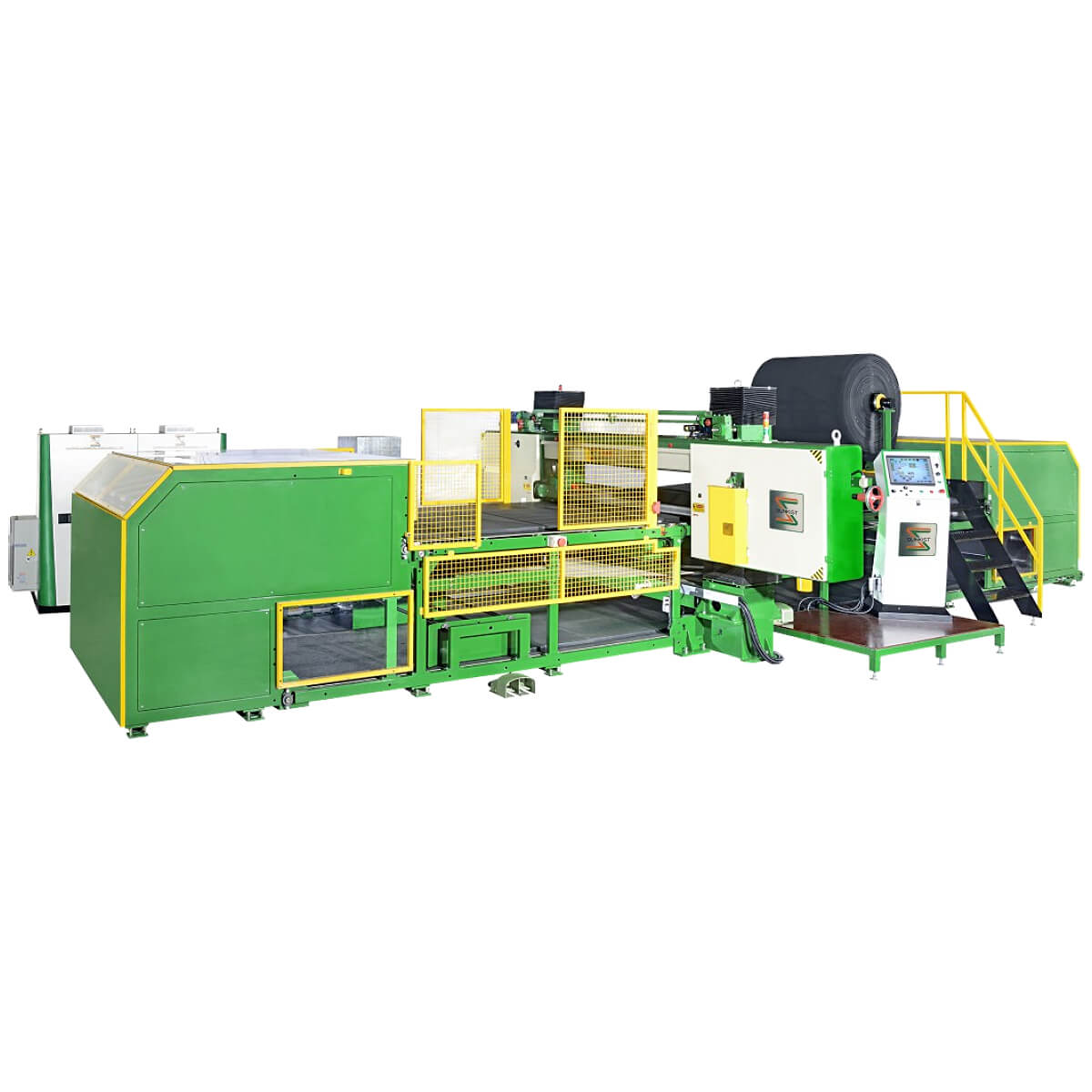

SA-2AHPR

SA-2AHPR

The Heavy Duty Looper is an upgraded long splitter that first glues a long foam block end-to-end, then runs the looping system to produce a long continuous foam sheet roll. The digital control panel calculates cutting thickness and length, and foam rolls can be easily removed for lamination. The SA-2AHPR is particularly good for high-density materials, as well as water- and shockproof materials; end products include diving suits, mouse pads, shoes, backpacks.The Heavy Duty Looper is an upgraded long splitter that first glues a long foam block end-to-end, then runs the looping system to produce a long continuous foam sheet roll. The digital control panel calculates cutting thickness and length, and foam rolls can be easily removed for lamination. The SA-2AHPR is particularly good for high-density materials, as well as water- and shockproof materials; end products include diving suits, mouse pads, shoes, backpacks.

-

SA-2AHPRL

SA-2AHPRL

Sunkist’s Large Looper System is designed for large-scale conversion plants to turn slabstock into rolled foam. The cast-steel cut head is adjustable by increments of 0.1mm, with automatic height and angle adjustments to follow the foam loop as it is peeled. The suction system underneath the perforated conveyor keeps foam well in place throughout the splitting and rolling operation.Sunkist’s Large Looper System is designed for large-scale conversion plants to turn slabstock into rolled foam. The cast-steel cut head is adjustable by increments of 0.1mm, with automatic height and angle adjustments to follow the foam loop as it is peeled. The suction system underneath the perforated conveyor keeps foam well in place throughout the splitting and rolling operation.