-

SA-6AC

SA-6AC

The SA-6AC is Sunkist’s most popular laminating machine, widely used throughout foam and foam-related industries. It has been used to laminate materials for manufacturing shoe soles, handbags, mattresses, and furniture pieces. This machine accepts both water- and solvent-based adhesives and is equipped with an electric heater to quickly dry laminated pieces for further processing.The SA-6AC is Sunkist’s most popular laminating machine, widely used throughout foam and foam-related industries. It has been used to laminate materials for manufacturing shoe soles, handbags, mattresses, and furniture pieces. This machine accepts both water- and solvent-based adhesives and is equipped with an electric heater to quickly dry laminated pieces for further processing.

-

SA-6AF

SA-6AF

The SA-6AF is Sunkist’s flame laminating machine. It applies heat and melts the surface of PE or PU foam sheets, to which other materials can be adhered. This “self-produced” adhesive, compared with other glues, guarantees stronger binding and less drying time. Foam melt is contained to 0.5mm of the material surface to save on production costs. This machine is ideal for manufacturing items like gloves and vehicle cushions.The SA-6AF is Sunkist’s flame laminating machine. It applies heat and melts the surface of PE or PU foam sheets, to which other materials can be adhered. This “self-produced” adhesive, compared with other glues, guarantees stronger binding and less drying time. Foam melt is contained to 0.5mm of the material surface to save on production costs. This machine is ideal for manufacturing items like gloves and vehicle cushions.

-

SA-6AH

SA-6AH

The SA-6AH is Sunkist’s hot melt adhesive laminating machine, primarily used by military and medical apparel suppliers. Hot melt adhesive requires a shorter drying time than water- or solvent-based adhesives, and is often used to manufacture apparel and footwear with functionalities such as waterproofing, breathability, and thermal protection. This machine also features top-of-the-line controls for lamination: gluing patterns and binding intensity can both be adjusted to precision, based on material types.The SA-6AH is Sunkist’s hot melt adhesive laminating machine, primarily used by military and medical apparel suppliers. Hot melt adhesive requires a shorter drying time than water- or solvent-based adhesives, and is often used to manufacture apparel and footwear with functionalities such as waterproofing, breathability, and thermal protection. This machine also features top-of-the-line controls for lamination: gluing patterns and binding intensity can both be adjusted to precision, based on material types.

-

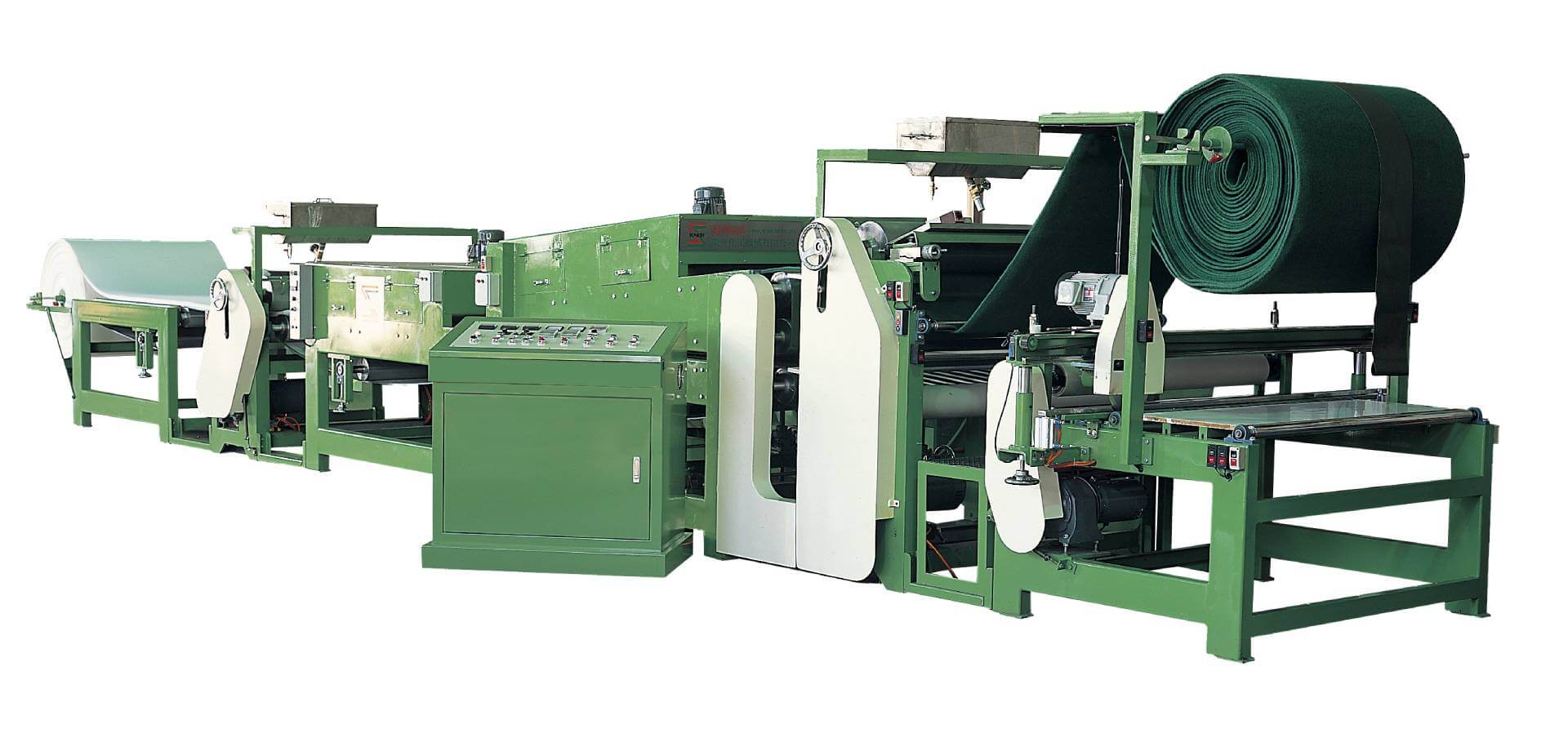

SA-6AS

SA-6AS

The SA-6AS is Sunkist’s scouring pad laminating machine that sticks scouring pads to foam sheets using either water- or solvent-based adhesives. The machine is also equipped with an electric heater to quickly dry laminated pieces to be ready for cutting. See our N-Series for a full line of nonwoven material production machines (including a machine to specifically manufacture scouring pads).The SA-6AS is Sunkist’s scouring pad laminating machine that sticks scouring pads to foam sheets using either water- or solvent-based adhesives. The machine is also equipped with an electric heater to quickly dry laminated pieces to be ready for cutting.

See our N-Series for a full line of nonwoven material production machines (including a machine to specifically manufacture scouring pads).

-

SA-6F

SA-6F

The SA-6F is Sunkist’s film laminating machine that binds rebonded foam sheets to PE film for manufacturing carpet underlays. The PE film surface is melted for adhesion, and no excess chemical adhesive will be present after processing. Hardy underlays significantly improve the quality and increase the lifespan of a carpet; the chemical coating on the plastic film protects the carpet from carpet beetles and absorbs excess moisture. The SA-6F is sold to major companies all over the world.The SA-6F is Sunkist’s film laminating machine that binds rebonded foam sheets to PE film for manufacturing carpet underlays. The PE film surface is melted for adhesion, and no excess chemical adhesive will be present after processing. Hardy underlays significantly improve the quality and increase the lifespan of a carpet; the chemical coating on the plastic film protects the carpet from carpet beetles and absorbs excess moisture. The SA-6F is sold to major companies all over the world.

-

SA-6MC

SA-6MC

The SA-6MC is Sunkist’s thermo foam laminating machine, specially designed to laminate PE and PP films by melting the film surface so as to not necessitate the addition of further adhesives. This machine is widely used to combine layers of film together for the use of cargo protection during the transportation of appliances and other crash-sensitive products.The SA-6MC is Sunkist’s thermo foam laminating machine, specially designed to laminate PE and PP films by melting the film surface so as to not necessitate the addition of further adhesives. This machine is widely used to combine layers of film together for the use of cargo protection during the transportation of appliances and other crash-sensitive products.