Maxfoam is a technique for continuous foaming, invented by machine manufacturer Laader Berg. In this article we’ll walk you through what Maxfoam actually does, its benefits and detriments, as well as alternatives.

Maxfoam: What it Actually Means

“Maxfoam” itself is the trademarked name of a number of Laader Berg continuous foaming machines. When we talk about the “Maxfoam process” in the industry, however, most of the time we’re referring to the trough.

A continuous foaming machine mixes polyol and TDI together. They then react on a running conveyor. As the liquid travels, it expands and gels into polyurethane slabstock (learn more about how PU foaming works here).

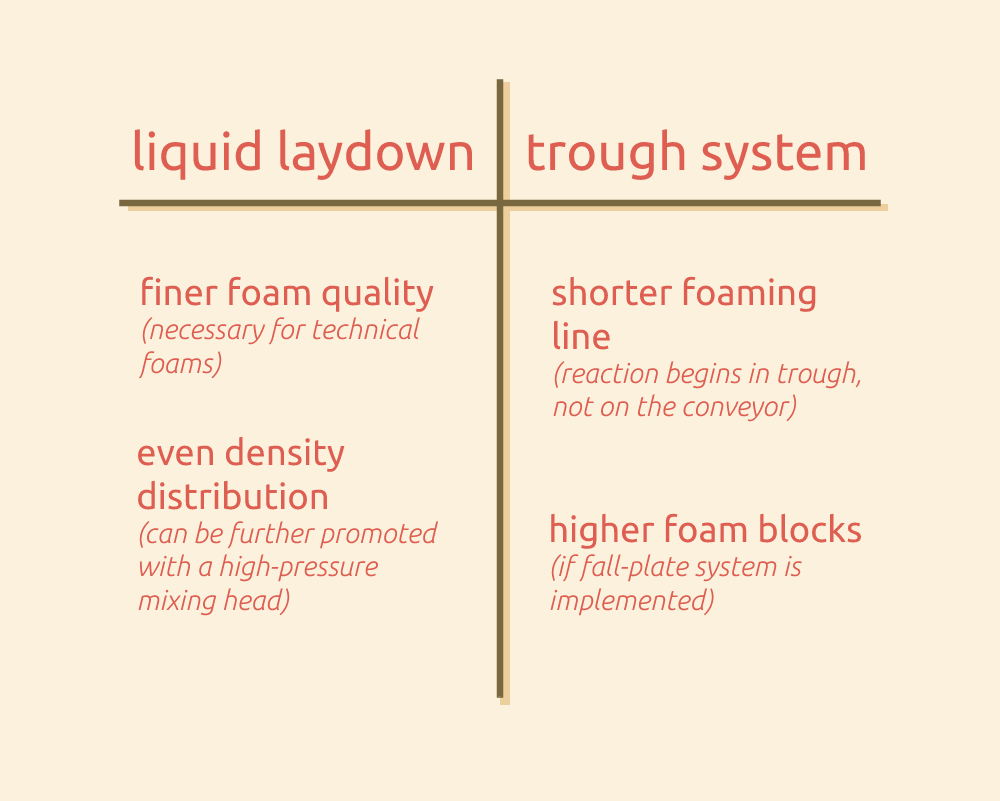

There are two primary ways the liquid chemicals can be introduced to the conveyor: by liquid laydown and by troughs.

Liquid Laydown

Let’s cover the liquid laydown method first because this was how continuous foaming was first done. Basically, chemicals are injected into a mixing head that hovers over the foaming conveyor. Liquid is “laid down” from that foaming head and the foaming process begins. This method is straightforward and easy to control. Foam produced by liquid laydown also has fewer pinholes. It’s also typically of finer quality, with fewer pinholes and a more uniform density throughout the block, making it the foaming method of choice for apparel and car interior foam manufacturers.

Trough Systems

Conversely, we have trough systems. Maxfoam is a trough system. Basically, a long trough is attached to the very front of the foaming conveyor. The foaming chemicals are fed into the trough by pipes along the bottom and as the trough fills, the liquid spills out onto the conveyor after some dwell time.

What are Maxfoam benefits then? Well, in a liquid laydown system, the chemist needs precise control over the conveyor speed. If the conveyor travels faster than the higher layers of foam can gel, the block begins to shear, and instead of vertically uniform foam you get torn layers. This is in part because the freshly mixed chemicals need a little time to react, and they can’t do that if a conveyor is constantly ripping their feet out from under them.

That’s where a trough system comes in handy. The chemicals begin to react during the dwell time, so when it pours onto the traveling conveyor, gellation happens more quickly and all at once.

Fall-plate Conveyor

Another characteristic of Maxfoam is its usage of fall-plates as the foaming conveyor. This means the foaming chemicals slope downward at a controlled angle as they expand and gel. Flat conveyors are the norm for continuous foaming, but this actually limits the maximum height the slabstock can expand to. This is because there is only one direction for expansion, and gravity can outweigh the upward potential of the reaction.

On a downward incline, however, slabstock can expand both upward and downward. If you’re looking to reduce material costs by maximizing product yield, consider a fall-plate conveyor.

High-Pressure Foaming

Speaking of reducing material costs, high-pressure foaming can help you reduce 2-4% of TDI loss during manufacturing. “High-pressure” refers to the chemical being injected into the mixing head, not onto the fall-plate itself. This method blends the chemicals more evenly, promoting faster and smoother reactions with less material waste. Plants foaming with polyester also require high-pressure foaming on account of the viscosity of their raw materials.

Conclusion

Laader Berg boasts that Maxfoam is the most prevalent continuous foaming method on the market. You’ve now learned the potential benefits and drawbacks of a trough system. Thinking of investing in continuous foaming? Consult a Sunkist plant-planning expert today.